Veolia E-Cell MK-3 EDI Stack for Continuous High-Purity Water Production

Detalhes do produto:

| Lugar de origem: | CHINA |

| Marca: | VEOLIA |

| Certificação: | CE |

| Número do modelo: | VEOLIA EDI Módulos E-Cell MK-3 |

| Documento: | Veolia EDI catalog.pdf |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1 pc |

|---|---|

| Preço: | negociável |

| Detalhes da embalagem: | Embalagem de exportação padrão |

| Tempo de entrega: | 5-8 dias de trabalho |

| Termos de pagamento: | T/T. |

| Habilidade da fonte: | 60000 unidades por mês |

|

Informação detalhada |

|||

| Produção máxima de água padrão (M3 /HR): | 4.5 | Produção mínima de água padrão (M3 /HR): | 1.6 |

|---|---|---|---|

| Recuperação padrão: | até 96% | Peso de envio padrão desta pilha: | 100 kg (220 libras) |

| Dureza padrão (ppm como caco3): | <1,0 | Sódio: | ≤ 3 ppb |

| Ácidos graxos: | Tão baixo quanto 0,08 ppb | Faixa de pH: | 4 a 11 |

| cor: | ≤ 5 APHA | Resistividade: | ≥ 16 MOHM-CM |

| Aplicação do módulo: | Preparação industrial de água de alta pureza | ||

| Destacar: | Veolia E-Cell MK-3 EDI stack,high-purity water production EDI stack,Suez EDI stack with warranty |

||

Descrição de produto

A pilha de eletrodeionização (EDI) Veolia E-Cell MK-3 foi concebida para a produção contínua de água de alta pureza,Remover eficazmente substâncias ionizadas e fracas ionizadas do permeado por osmose reversa (RO)O sistema fornece água ultrapura com uma resistividade de até 18 MΩ·cm sem necessidade de regeneração química, reduzindo os custos operacionais e o impacto ambiental.Ideal para indústrias como a geração de energia, produtos farmacêuticos, microeletrônicos e semicondutores, a pilha MK-3 garante desempenho confiável, altas taxas de recuperação do sistema e operação estável em condições variadas.Sua construção robusta permite uma longa vida útil e manutenção mínima, tornando-se um componente crítico nos sistemas industriais de purificação de água

| Atributo | Valor |

|---|---|

| Produção máxima de água (m3/h) | 4.5 |

| Produção mínima de água (m3/h) | 1.6 |

| Recuperação | Até 96% |

| Peso do transporte | 100 kg (220 libras) |

| Dureza (ppm em CaCO3) | < 1.0 |

| Sódio | ≤ 3 ppb |

| Ácidos graxos | Até 0,08 ppb |

| Intervalo de pH | 4 a 11 |

| Cores | ≤ 5 APHA |

| Resistividade | ≥ 16 MOhm-cm |

| Aplicação | Preparação industrial de água de alta pureza |

Tecnologia de eletrodeionização contínua de nível industrial que utiliza campos elétricos de corrente contínua para impulsionar a migração de íons, combinando resinas de troca de íons e membranas seletivas para remoção contínua de impurezas.

- Regeneração eletroquímica in situ: Elimina a regeneração química ácido/base

- Projeto de três canais: A operação contracorrente reduz os riscos de escalagem (perda de pressão verificada: 1,4-3,4 bar)

- Operação sem produtos químicos: Cumprir as normas ISO 14001

- Modularidade compacta: Profundidade da série MK 29-74 cm para eficiência de espaço

- Desinfecção térmica: Suporta a desinfecção com água quente a 85°C (≥160 ciclos), cumprindo os cGMP

- Optimização energética: 20% de redução do consumo de energia em relação ao EDI convencional (0-400 VDC)

| Parâmetro | Valor |

|---|---|

| Fluxo nominal | 3.4 m3/h (15 gpm) |

| Intervalo de taxa de fluxo | 1.7 - 4,5 m3/h (7,0 - 20 gpm) |

| Dimensões (W x H x D) | 30 cm x 61 cm x 54 cm (12" x 24" x 22") |

| Qualidade da água do produto | Resistividade ≥ 16 MOhm-cm, Sódio ≤ 3 ppb, Silício ≤ 5 ppb, Boro ≤ 0,08 ppb |

| Eficiências de remoção | Sódio ≥ 99,9%, Silício até 99%, Boro até 96% |

| Parâmetros de funcionamento | Voltagem 0-300 VDC, Amperagem 0-5,2 ADC, Pressão de entrada ≤ 6,9 bar |

- Água ultrapura para lavagem de chips de semicondutores e microeletrónica

- Água de alimentação para caldeiras desmineralizada para usinas de energia e instalações industriais

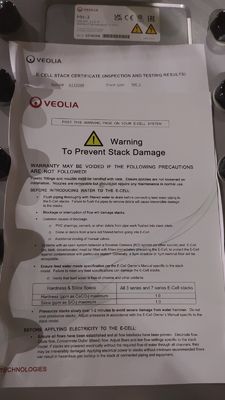

- Certificado CE, RoHS, CSA e EAC

- Fabricação em conformidade com as normas ISO 9001 e ISO 14001

- Certificado UKCA

- Halal certificado pela IFANCA®