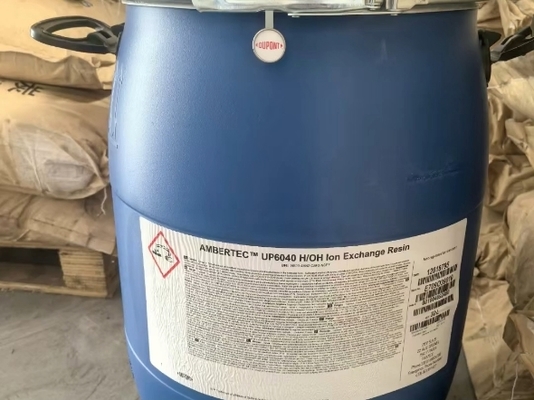

DuPontTM AmberTecTM UP6040 Resina de Troca de Íons H/OH para Aplicações em Água Ultrapura

Detalhes do produto:

| Lugar de origem: | CHINA |

| Marca: | Dupont |

| Certificação: | ISO9001 |

| Número do modelo: | DuPont ™ Ambertec ™ UP6040 H/OH |

| Documento: | IER-AmberTec-UP6040-H-OH-PD...en.pdf |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1pc |

|---|---|

| Preço: | negociável |

| Detalhes da embalagem: | Embalagem de exportação padrão |

| Tempo de entrega: | 5-8 dias de trabalho |

| Termos de pagamento: | T/T. |

| Habilidade da fonte: | 60000 unidades por mês |

|

Informação detalhada |

|||

| Resistividade (UPW enxágüe, 10 minutos): | ≥ 18 MΩ · cm | Resistividade (Salt Challenge, 10 minutos): | ≥ 18 MΩ · cm |

|---|---|---|---|

| Δtoc (2H00 enxágue): | ≤ 3 ppb c | Aplicações primárias: | Aplicações de água ultrapura |

| Grupo funcional da resina de catátio: | Ácido sulfónico | CAPATION RESINA CAPACIDADE: | ≥ 2,00 Eq/L. |

| Destacar: | DuPont AmberTec UP6040 ion exchange resin,H/OH ion exchange resin for ultrapure water,water treatment consumables with ion exchange resin |

||

Descrição de produto

1. Visão geral do produto

O AmberTecTM UP6040 H/OH é umTamanho de partícula uniforme e não separávelResina de intercâmbio iónico de leito misto, concebida para:Poluição final em sistemas de água ultrapura (UPW)O sistema de detecção de emissões de CO2 é utilizado na indústria de semicondutores e noutras aplicações exigentes.Em sistemas UPW bem concebidos, fornece água com18Resistividade de 0,2 MΩ·cmeNíveis de TOC inferiores a 1 ppb.

![]()

Características principais:

-

Tamanho uniforme de partícula não separável

-

Alta resistência, limpeza e pureza

Principais aplicações:

-

Água ultrapura para fabrico de semicondutores e aplicações semelhantes de alta pureza

2. Propriedades típicas

Propriedades físicas e químicas:

| Imóveis | Resina catiónica | Resina aniônica |

|---|---|---|

| Copolimero | Estireno-divinilbenzeno | Estireno-divinilbenzeno |

| Matriz | Gel | Gel |

| Tipo | Cation de ácido forte | Aníon base forte, tipo I |

| Grupo funcional | Ácido sulfónico | Trimetilamónio |

| Forma física | Esferas translúcidas de cor âmbar escura | Perlas esféricas translúcidas amarelas |

| Forma iónica conforme enviada | H+ | Oh- |

| Capacidade de troca total | ≥ 2,00 eq/L | ≥ 1,10 eq/L |

| Capacidade de retenção de água | 45 ️ 51% | 54 ¢ 60% |

| Conversão iónica (H+) | ≥ 99% | - Não. |

| Conversão iónica (OH−) | - Não. | ≥ 95,0% |

| Conversão iónica (CO32−) | - Não. | ≤ 5,0% |

| Conversão iónica (Cl−) | - Não. | ≤ 0,5% |

Distribuição do tamanho das partículas:

| Parâmetro | Resina catiónica | Resina aniônica |

|---|---|---|

| Diâmetro da partícula | 525 ± 50 μm | 630 ± 50 μm |

| Coeficiente de uniformidade | ≤ 120 | ≤ 120 |

| < 300 μm | ≤ 0,1% | - Não. |

| < 425 μm | - Não. | ≤ 0,5% |

| > 850 μm | ≤ 5,0% | - Não. |

| > 1180 μm | - Não. | ≤ 2,0% |

i Para informações adicionais sobre o tamanho das partículas, ver o documento n.o: 45-D00954-en.

3. Desempenho e condições de funcionamento

Resultados do ensaio de qualidade da água ultrapura:

-

Resistividade (Lançamento UPW, 10 min):≥ 18 MΩ·cm

-

Resistividade (Salt Challenge, 10 minutos):≥ 18 MΩ·cm

-

ΔTOC (2h00 Enxaguar):≤ 3 ppb C

Condições de funcionamento recomendadas:

-

Intervalo de temperatura:15° 25° C (59° 77° F)

-

Intervalo de pH (estável):0 14

-

Peso do transporte:710 g/l

- A operação a temperaturas elevadas (por exemplo, > 60 ∼ 70 °C) pode afectar a pureza do sistema e a duração da resina.

4Características hidráulicas

-

Diminuição de pressão:A estimativa da queda de pressão em função do caudal de serviço e da temperatura é apresentada na figura 1 (ver documento original para curvas pormenorizadas).

-

Performance do enxaguante:As curvas típicas de resistividade e TOC de enxaguamento em função do tempo de enxaguamento são apresentadas na Figura 2.

5Garantia da qualidade e segurança

-

Garantia da qualidade:Todos os lotes são testados para a resistividade do enxaguante, TOC e desempenho cinético para atender aos rigorosos requisitos UPW.

-

Alerta:Agentes oxidantes fortes (por exemplo, ácido nítrico) podem atacar a resina sob certas condições, levando à degradação ou a reações violentas.

-

Os utilizadores devem rever os processos de fabrico e as aplicações a partir de perspectivas de saúde, segurança e ambiente.

-

Consulte a última Ficha de Dados de Segurança (FDS) antes de a utilizar e certifique- se de que está em conformidade com a regulamentação local.

Os utilizadores devem rever os processos de fabrico e as aplicações a partir de perspectivas de saúde, segurança e ambiente.Consulte a última Ficha de Dados de Segurança (FDS) antes de a utilizar e certifique- se de que está em conformidade com a regulamentação local..

A FG Water Technologies (www.fgwater.com) é agora uma parte orgânica da Wuxi Fenigal Science and Technology Co. Ltd., que é uma entidade de alta tecnologia que integra o design de equipamentos de tratamento de água, a fabricação,O comércio e a navegação servem os principais sectores industriais.

A HAFE-FG Water Technologies tem-se concentrado na investigação da tecnologia de tratamento de água, desenvolvimento e fabrico de equipamentos, testes e embarque internacional, etc.Trabalhamos com muitos dos principais fabricantes de equipamentos originais de pequena ou média escala em zonas de desenvolvimento de alta tecnologia da China, e nos envolvemos em P&D, fabricação e testes de qualidade.

Os nossos principais produtos incluem uma variedade de equipamentos de purificação e tratamento de água, tais como sistema de osmose inversa de água do mar (SWRO), sistema de osmose inversa de água salobra (BWRO),sistema de ultrafiltração (UF)Até agora, a nossa empresa tornou-se um dos principais fornecedores de equipamentos de tratamento de água para a indústria de alimentos e bebidas.indústria farmacêutica, indústria química, indústria eléctrica, indústria de abastecimento de água urbana, tratamento de águas residuais municipais e industriais e mais indústrias,Além de ser exportador para mais de 20 países e regiões da Ásia, Europa, Américas, África, etc.

O nosso sistema de produção consiste numa lista de fábricas de parceria especializadas na indústria em toda a China.000 m2 de oficina e armazém e 1Todos os nossos técnicos têm mais de 10 anos de experiência na concepção de sistemas de tratamento de água,Assim, somos capazes de fornecer a solução perfeita para todos os tipos de aplicações de purificação de água e tratamento de esgoto.

Desde a sua criação, a empresa sempre considerou a qualidade como a vida do nosso negócio.Os nossos sistemas são fáceis de usar e manter, e permanecem altamente fiáveis mesmo nas condições mais difíceis.