DHP 0.6 Axial Piston Pump (0.6m³/h, 80Bar) – High-Pressure Water Treatment Consumables for Small/Medium Desalination

Detalhes do produto:

| Lugar de origem: | China |

| Marca: | Fenigal |

| Certificação: | CE |

| Número do modelo: | DHP 0.6 |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1 pc |

|---|---|

| Preço: | negociável |

| Detalhes da embalagem: | Embalagem de exportação padrão |

| Habilidade da fonte: | 60000 unidades por mês |

|

Informação detalhada |

|||

| Modelo de produto: | DHP 0.6 | Deslocamento geométrico: | 3,62 cm³/rev |

|---|---|---|---|

| Fluxo nominal na velocidade nominal (3000 rpm): | 0,6 m³/h (equivalente a 10 l/min em vazão de minuto) | Pressão mínima de saída: | 10 bar |

| Pressão de saída contínua máxima: | 80 bar (para requisitos de pressão mais alta ou mais baixa, entre em contato com o representante de | ||

| Destacar: | high-pressure axial piston pump,0.6m³/h water treatment pump,desalination consumables with 80Bar |

||

Descrição de produto

Core Technical Parameters of DHP 0.6

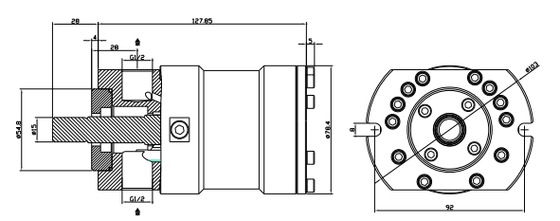

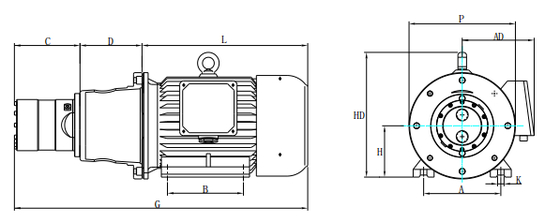

Inlet & Outlet Dimensions of DHP 0.6

Overall Dimensions of DHP 0.6 (Unit: mm)

Manufacturer Contact Information

![]()

Deseja saber mais detalhes sobre este produto