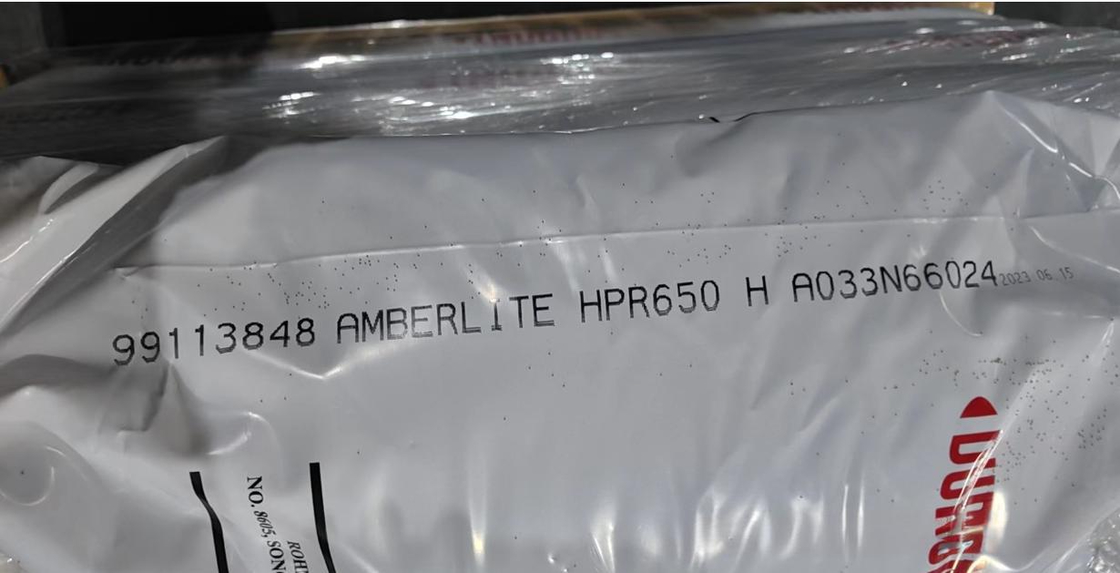

Resina de troca iônica DuPont AmberLite HPR4200 Cl para desmineralização de água industrial com esferas inteiras não rachadas ≥ 90% e inchamento de 20%

Detalhes do produto:

| Lugar de origem: | CHINA |

| Marca: | Dupont |

| Certificação: | ISO9001 |

| Número do modelo: | Dupont ™ Amberlite ™ HPR4200 CL |

| Documento: | IER-AmberLite-HPR4200-Cl-PD...en.pdf |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1pc |

|---|---|

| Preço: | negociável |

| Detalhes da embalagem: | Embalagem de exportação padrão |

| Tempo de entrega: | 5-8 dias de trabalho |

| Termos de pagamento: | T/T. |

| Habilidade da fonte: | 60000 unidades por mês |

|

Informação detalhada |

|||

| Principais aplicações do HPR4200 CL: | Desmineralização de Água Industrial | Contas inteiras não quebradas HPR4200 CL: | ≥ 90% |

|---|---|---|---|

| HPR4200 CL Inchaço (Cl⁻ → OH⁻): | 20% | Densidade de partículas HPR4200 CL: | 1,07 g/ml |

| Aviso HPR4200 CL: | Agentes oxidantes fortes (por exemplo, ácido nítrico) podem degradar a resina ou causar reações viol | Forma Física HPR4200 CL: | Contas esféricas translúcidas amarelas |

| Tipo: | Ânion de base forte, tipo I | ||

| Destacar: | Resina de troca iônica com esferas inteiras não rachadas,Inchamento de 20% AmberLite HPR4200 Cl,Densidade de partículas 1 |

||

Descrição de produto

DuPontTM AmberLiteTM HPR4200 Cl Resina de Troca de Íons para Desmineralização Industrial de Água

A DuPontTM AmberLiteTM HPR4200 Cl é uma resina de troca de aniões de base forte, de tamanho uniforme, gel, Tipo I, de alta qualidade, projetada para aplicações industriais de desmineralização de água.É enviado na forma de cloreto (Cl−).

Visão geral do produto

Esta resina foi concebida para proporcionar uma elevada capacidade de funcionamento e uma baixa queda de pressão, o que contribui para reduzir o consumo de produtos químicos durante a regeneração e reduzir os requisitos de água de enxaguamento,oferecer uma operação rentávelAs suas propriedades químicas e físicas equilibradas tornam-na uma escolha versátil e de alto desempenho para vários sistemas de tratamento de água.

Aplicações

- Desmineralização

- Ideal para o tratamento de águas com uma elevada percentagem de sílica

- Eficaz para remover ácidos fortes e fracos e alcançar uma baixa fuga de sílica

- Poluição de camas mistas

Projetos de sistemas compatíveis

- Camas mistas

- Camas de embalagem

- Camas em camadas

- Sistemas de contracorrente / retenção

- Sistemas de corrente simultânea

Emparelhamentos de resinas recomendados

- Para camas mistas:

- AmberLiteTM HPR1200 H (gel)

- AmberLiteTM HPR1300 H (gel)

- Para camas em camadas:

- AmberLiteTM HPR9500 (macroporoso)

- AmberLiteTM HPR9600 (macroporoso)

Referência histórica

Anteriormente vendido comoDOWEX MARATHONTM 4200 Cl Resina de Troca de Íons.

Propriedades típicas

Propriedades físicas

| Imóveis | Especificações |

|---|---|

| Copolimero | Estireno-divinilbenzeno |

| Matriz | Gel |

| Tipo | Aníon base forte, tipo I |

| Grupo funcional | Trimetilamónio |

| Forma física | Perlas esféricas translúcidas amarelas |

Propriedades químicas

| Imóveis | Especificações |

|---|---|

| Forma iónica (conforme enviada) | Cl− |

| Capacidade de troca total | ≥ 1,30 eq/L (forma Cl−) |

| Capacidade de retenção de água | 49.0 - 55,0% (Cl− forma) |

Distribuição do tamanho das partículas

| Parâmetro | Especificações |

|---|---|

| Diâmetro da partícula | 650 ± 50 μm |

| Coeficiente de uniformidade | ≤ 125 |

| < 300 μm | ≤ 0,3% |

| > 850 μm | ≤ 5,0% |

Para informações adicionais sobre o tamanho das partículas, ver o documento n.o 45-D00954-en.

Estabilidade

- Perlas inteiras não quebradas:≥ 90%

- Inchaço (Cl− -> OH−):20%

Densidade

- Densidade de partículas:10,07 g/ml

- Peso do transporte:670 g/l

Condições de funcionamento

- Intervalo de temperatura:

- Forma OH-5 - 60°C (41 - 140°F) †

- Cl− forma:5 - 100°C (41 - 212°F)

- Intervalo de pH:

- Ciclo de serviço:1 - 14

- Estável:0 - 14

† O funcionamento a temperaturas elevadas (por exemplo, > 60-70°C) pode afectar a duração da resina.

Características hidráulicas

- Expansão do backwash:A estimativa da expansão do leito em função da taxa de caudal e da temperatura de refluxo é apresentada na Figura 1.

- Diminuição de pressão:A estimativa da queda de pressão em função do caudal de serviço e da temperatura é apresentada na figura 2 (válida para água limpa no início do funcionamento).

(Nota: ver documento original para dados gráficos.)

Segurança e conformidade

Aviso:Agentes oxidantes fortes (por exemplo, ácido nítrico) podem degradar a resina ou causar reações violentas.

Os utilizadores devem rever as fichas de dados de segurança (FDS) e assegurar a conformidade com a regulamentação local.

Deseja saber mais detalhes sobre este produto